Quality Assurance

At HTS we believe that we earn your continuous trust as Your reliable partner for EMS by always delivering products that meet or exceed your quality requirements. We employ a strict Quality Management System (QMS) to control the whole production process, so that quality is assured at every level of assembly.

Continuous Improvement

Continuous Improvement is initiated through the use of quality policy, quality objective, analysis of data, corrective and preventive actions and management review. This requirement covers both the reactive and proactive action of improvement.

The reactive actions are those actions taken to address nonconformities on products, processes and systems, as an example the correction taken on a nonconformity or a defect and the follow-up corrective actions to remove the root causes of the nonconformity.

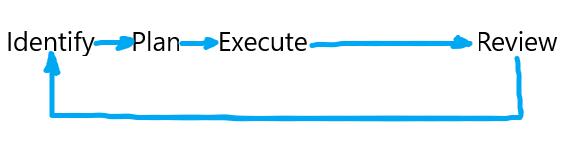

The cyclicity, shown above, ensures rigor that is necessary for understand all aspects of the improvement opportunities and for considering multiple options. CI tools, apart the data analysis tools, also include creativity tools, quality functions deployment and what-if analysis. In the context of CI, it is necessary to focus in more depth on customer’s wants and needs in order to be able to develop improvement options. This kind of approach involves more sophisticated research and the requirement to obtain additional customer data in order to determine the scope of the improvement.

| ACCREDITATIONS | ||

| IATF16949:2016 |

ISO9001:2015 | ISO14001:2015 |